PCBs are still the most dependable and efficient means to connect electrical components. Electronic components are soldered on pads connected by conductive lines on a printed circuit board, or PCB. PCB manufacturing technology is evolving as downsizing, reliability, and flexibility become more important. They are available in a variety of forms, colors, and base materials and they can even be flexible.

PCBs are still "printed," but the technology now

includes numerous equally crucial phases in addition to the printing process.

As a result, PCB makers must adapt to new trends and give the finest services

possible.

PCBWay is a PCB manufacturing firm established in China that

produces over 2100 PCBs each day for distribution globally. They have five

facilities with over 520 personnel that offer a wide range of PCB prototyping,

assembly, design, and CNC/3D printing services.

PCBWay delivers top-notch services at extremely competitive

pricing by investing in new equipment, quality control, and user support. The

firm distinguishes out for its extensive range of technical assistance and

user-friendly website, but most importantly, for its strong community support.

From Prototype to Assembly to Product - PCBWay

PCBWay offers everything needed to complete electronics projects, with over 70 on-staff specialists ensuring zero-defect quality assurance and quick delivery. To simplify its clients' journey to commercial goods, the firm gets materials from well-known companies and maintains ISO 9001 and UL certifications.

PCB prototype is generally the first step in the process of

developing such goods. As one of their most popular services, the firm can

produce PCBs of practically any size, shape, or complexity, allowing you to customize

board characteristics such as base materials, thicknesses and number of layers,

silkscreen colors, solder masks, surface treatments, and so on.

PCBWay works with the following

basic base materials:

Rigid

PCBs — these high-tech, high-quality boards are often reserved for

high-frequency electronics, automotive subsystems, and other demanding

applications, and are based on HDI/Rogers/High-Tg technology.

Aluminum

PCBs - PCBWay clients may select between improved power dissipation

qualities and higher mechanical stability of material with two types of aluminum

PCBs – central and base core.

Thick-Copper

PCBs - For superior thermal performance and other particular features,

an aluminum basis can be replaced with copper, although at a greater cost. Smartphones,

cameras, and nonstandard portable gadgets or small electronics can all benefit

from flexible PCBs. To get around enclosure limits, you may push them into tiny

areas, bend and wrap them.

Flexible PCB — this technology combines rigid and flexible PCBs into a single unit without the need for extra connections. Manufacturing becomes simpler and less expensive while taking advantage of both technologies.

More than 10 layers per board are possible, with traces as

tiny as 4 mm, drill sizes as small as 0.2 mm, and plated hole sizes as small as

0.6 mm. PCBWay consultations can lead to innovations that push these boundaries

even further.

The company's assembly service, which is necessary after the prototype, is another important stage in the PCBWay process. Solder paste

stencils are used to apply solder paste, components are placed, and soldering

is done. Because it normally entails installing hundreds of microscopic SMT

components on the PCB surface, it is a labor-intensive procedure that is done

by a machine.

PCBWay has all of the components and equipment needed to

create and automate a high-quality, high-reliability assembly process for your

project. They do, however, allow you to furnish some or all of your own

components, which is useful if your design comprises rare or unusual elements

that require special care. Otherwise, the turnkey solution is the best choice.

Today is Chinese Valentine's Day, because in Chinese language the date May 20th, aka 520 means I love you.

— PCBWay (@PCBWayOfficial) May 20, 2022

Thought this heart shape PCB finally has an occasion for sharing :D Wish everyone a great Friday!#pcb #pcbway pic.twitter.com/hP2PAzKVrG

You may start the assembly service by filling out an online

form that lets you to choose the supply amount, board type, number of unique

SMT pads, and thru-holes. It also has places where you may give more

information and detail about your request, which can speed up the assembly process.

After entering the required information, you will receive an

immediate price that includes production and delivery charges. PCB prototypes

that aren't too complicated can cost as little as $5, while PCB assembly can

cost as little as $30. (Without parts).

Turnaround times can be as short as a few days, with one day

for prototyping, another for assembly, and finally delivery.

PCBWay offers a variety of shipping options according to the

target country, with prices varying across carriers such as DHL, FedEx, China

Post, UPS, and others. PayPal, Western Union, VISA, and Direct Bank Transfer

are all acceptable payment options.

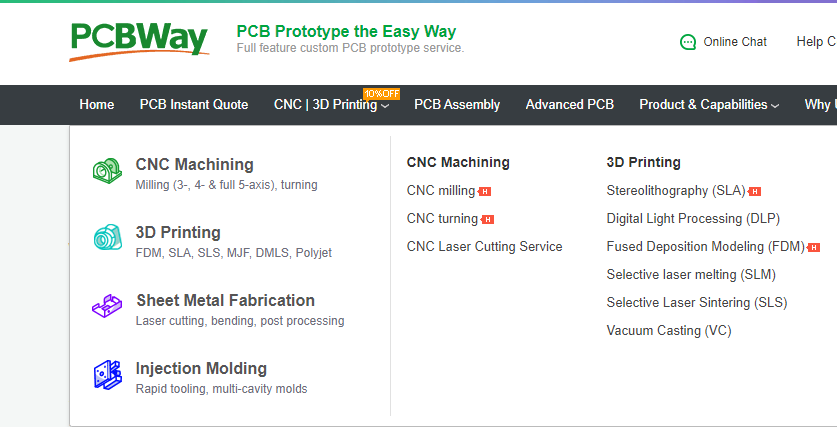

PCBWay also provides a quick system prototype for enclosures

and other nonstandard mechanical elements that are required for a final

product. They support four different rapid prototyping techniques:

CNC

Machining — Once CAD files are generated and loaded, this sturdy

technology uses milling and turning to swiftly make many pieces.

Sheet

Metal Fabrication - They must prepare press and cutting forms based on

CAD files, and there is no limit to the number of pieces they may produce. Once

set up, the procedure is quick. Anodizing, plating, powder coating, and

painting are among the options for finishing finished objects.

PCBWay's 3D printing procedures vary depending on the

materials used, but they all revolve around focused deposition modeling (FDM),

selective laser sintering (SLS), and stereolithography (SLA).

Injection

Molding — this method of producing components, usual enclosures,

involves pressing hot plastic into moulds to obtain great accuracy across huge

quantities of complicated parts.

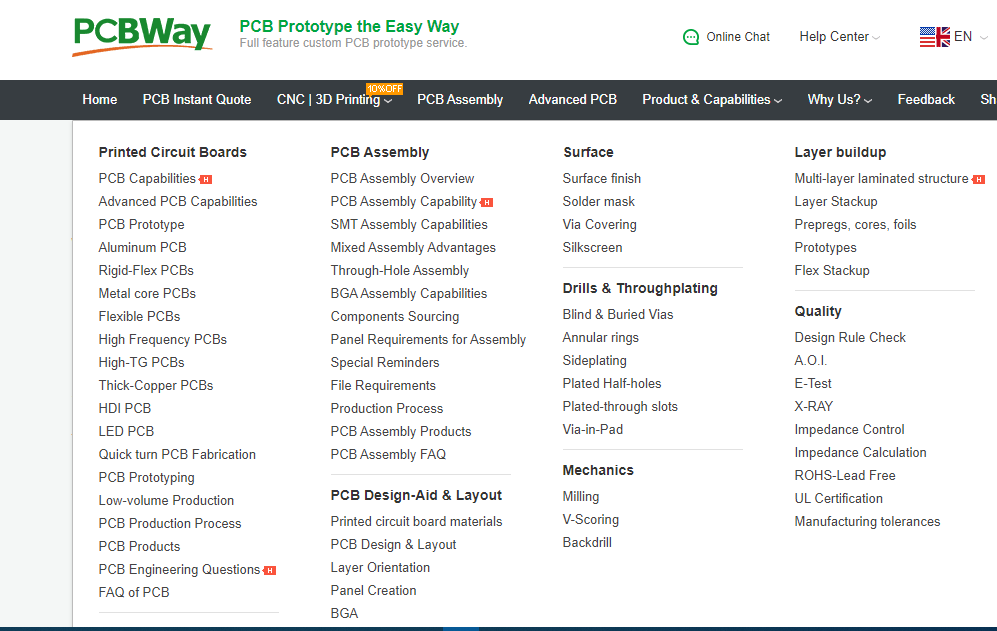

User-Friendly Website - PCBWay

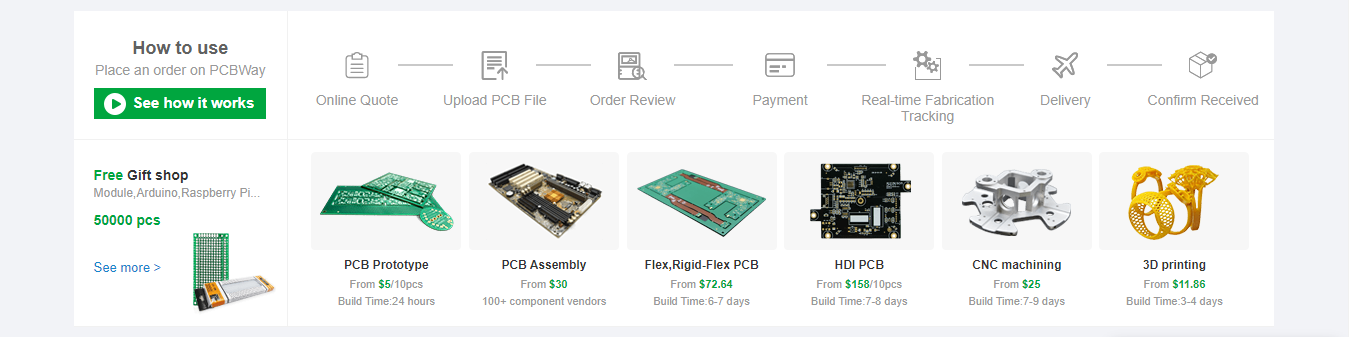

As previously said, the PCBWay website is well-designed and user-friendly. The main page clearly outlines the offered services, their prices, and how they function, and it can also be used to check order status and progress.

A directory of the most common PCBs, cost by volume

estimates, and other factors are all presented in an easy-to-read chart on the

PCBWay site. This allows purchasers to estimate the cost of ordering 100

two-layer PCBs or 500 aluminum boards, for example.

A directory of the most common PCBs, cost by volume

estimates, and other factors are all presented in an easy-to-read chart on the

PCBWay site. This allows purchasers to estimate the cost of ordering 100

two-layer PCBs or 500 aluminum boards, for example.

Each service has its own page on the user-friendly website,

although they can all be accessible from the main page. Once you've signed up

for the service you want, the fast quote calculator may give you an idea of how

much your project will cost and link you to a more formal ordering form where

you can obtain a formal, full estimate.

The primary buying page of the PCBWay website is in English,

but there are also professionally translated sites in Russian, Spanish, French,

and Japanese.

PCBWay has built a robust community of over a

quarter-million registered users who both contribute and profit from being a

"PCBWay." Projects may be shared with the community, and members can

seek sponsorship and financing. PCBWay has supported over 23000 schools,

open-source initiatives, events, conferences, and tradeshows, including Maker

Faire, too far.

PCBWay also hosts shopping festivals, raffles, and bargains

for members, with prizes, cash awards, and discounts for those who participate.

All you have to do to join the community is register. After completing that

step, you'll be able to utilize the services immediately and will receive a

discount code to use on your first order.

Because the PCB manufacturing business is so competitive,

prospective consumers should shop around for the best pricing, quality,

delivery time, and customer service. Whether you require a single little PCB or

a complicated, multi-layer Rigid or Flexible PCB, PCBWay excels in all of these

areas.

Visit www.pcbway.com to view the results for yourself, and

start creating a quotation for your next job.

0 Comments